Textile core materials:

- High tenacity polyester

- Texturised polyester

- Cotton, Nylon

- Para-aramid and meta-aramid yarns

- Glass fibre yarn

Winding materials:

- Copper, Tin plated copper

- Silver plated copper, Nickel plated copper

- CuNi and NiCr alloys, Nichel, Brass

- Aluminium, Steel

- Silver, Gold

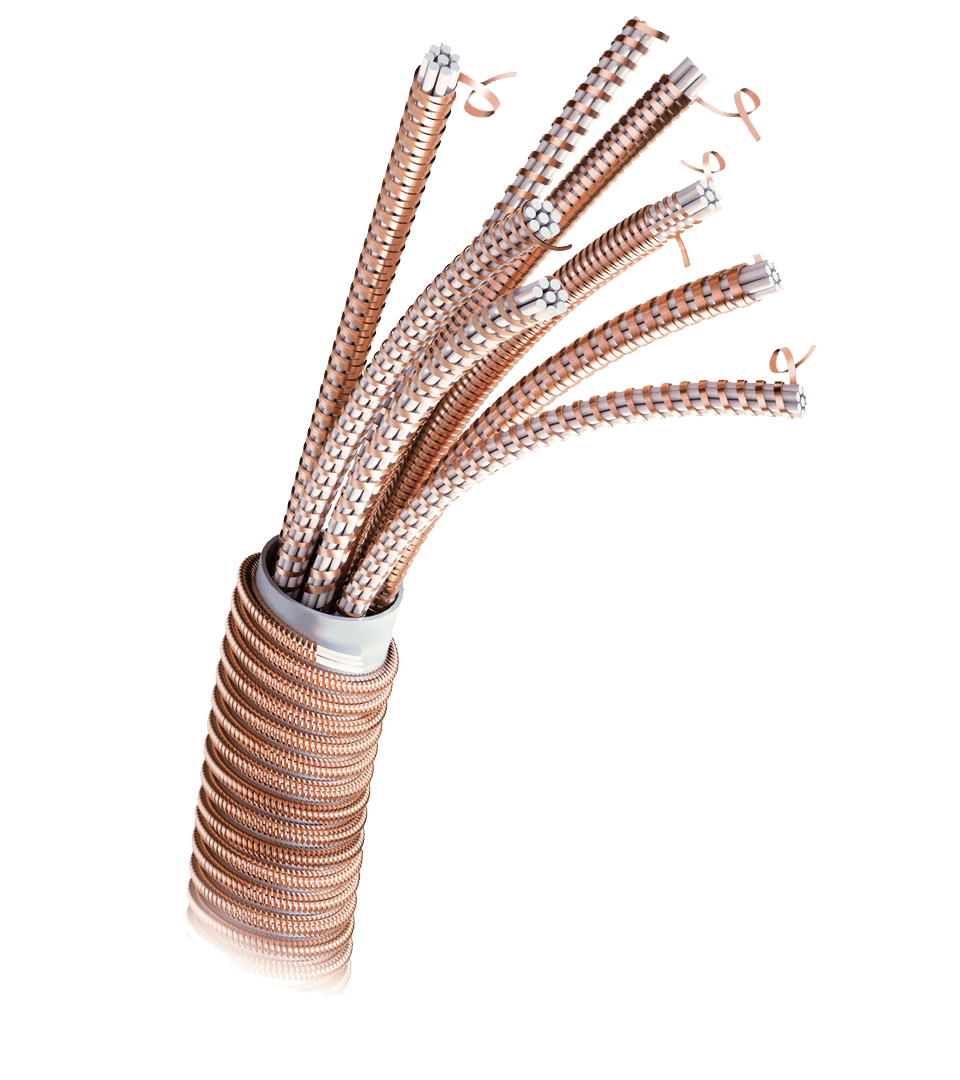

Tinsel

Tailor made shielding

Textile core materials:

- High tenacity polyester

- Texturised polyester

- Cotton, Nylon

- Para-aramid and meta-aramid yarns

- Glass fibre yarn

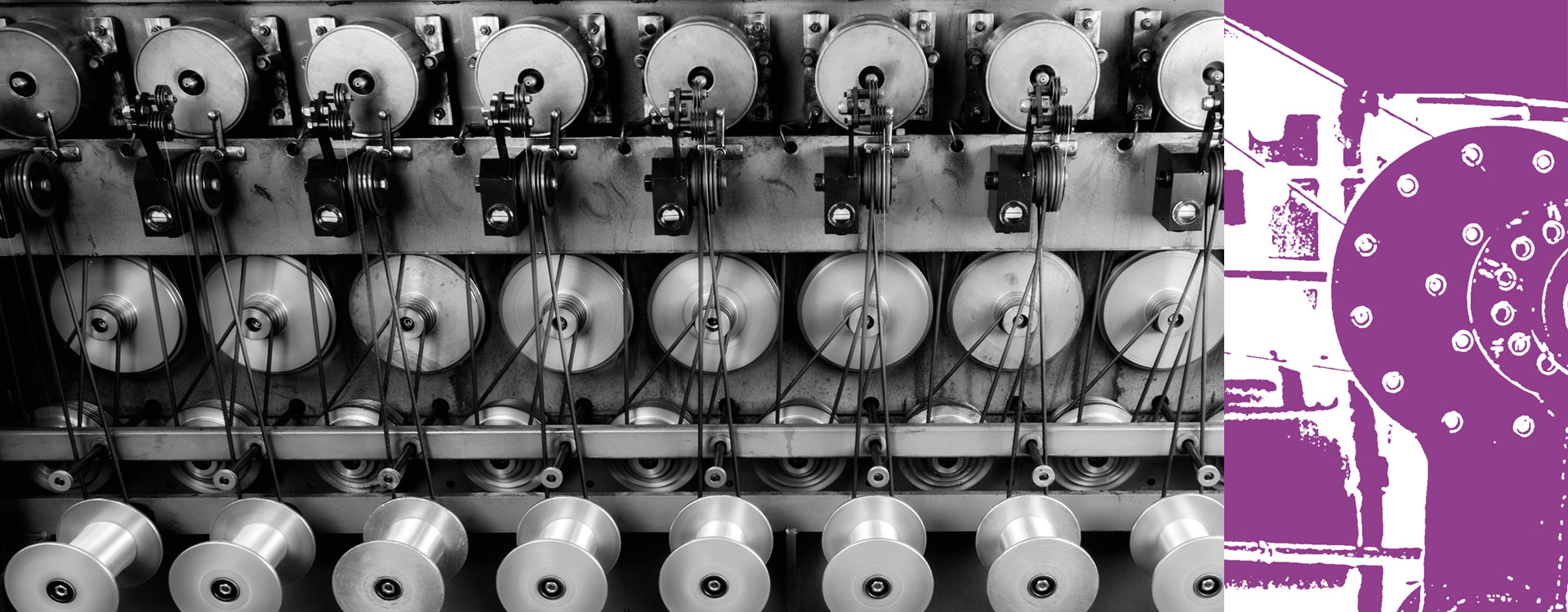

Winding materials:

- Copper, Tin plated copper

- Silver plated copper, Nickel plated copper

- CuNi and NiCr alloys, Nichel, Brass

- Aluminium, Steel

- Silver, Gold

Tinsel

Tailor made shielding

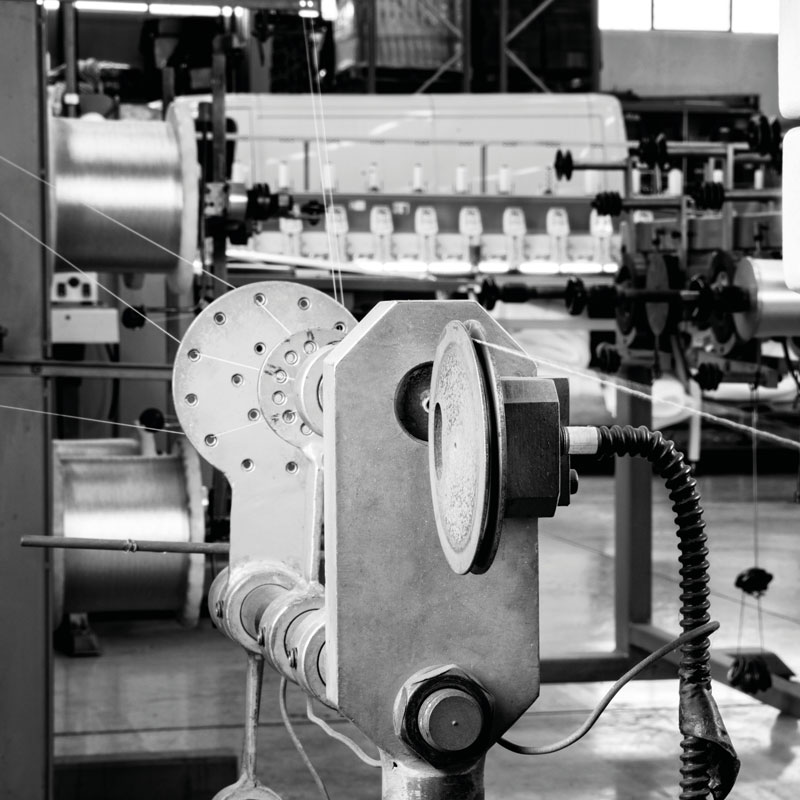

Unique technology in 0.1mm diameter

High resistance to torsional and bending stress.

A strong, clean signal

The final result also depends on the ability to identify premium materials, from qualified and carefully selected suppliers, to meet the highest performance standards.

By combining quality materials with a know-how developed over time, we are able to respond to any request, for a high level shielding that ensures a clean and interference-free signal and also guarantees

Key features, for example, for use in mechanical arms of latest generation robots.

That is why our Tinsel reach such a wide consensus in the special cables field, especially in cables for electro medical equipment, robotics, and telephony.

Our in-house laboratory allows us to test different solutions to achieve superior performance.

A complex project

In order to meet the demands of certain characteristics, it may be necessary to combine several Tinsel strands, even with different windings, stranded or braided according to specific requirements.

The purpose of this process is to achieve significantly low electrical resistance values, while ensuring an unsorpassed softness and flexibility of the cable.

Only the correct calibration of all these parameters, defined in collaboration with customers and their technical teams, along with the manufacturing of the product to top workmanship standards, allows us to obtain that perfect cable that can be used in sophisticated equipment where maximum reliability is the key.